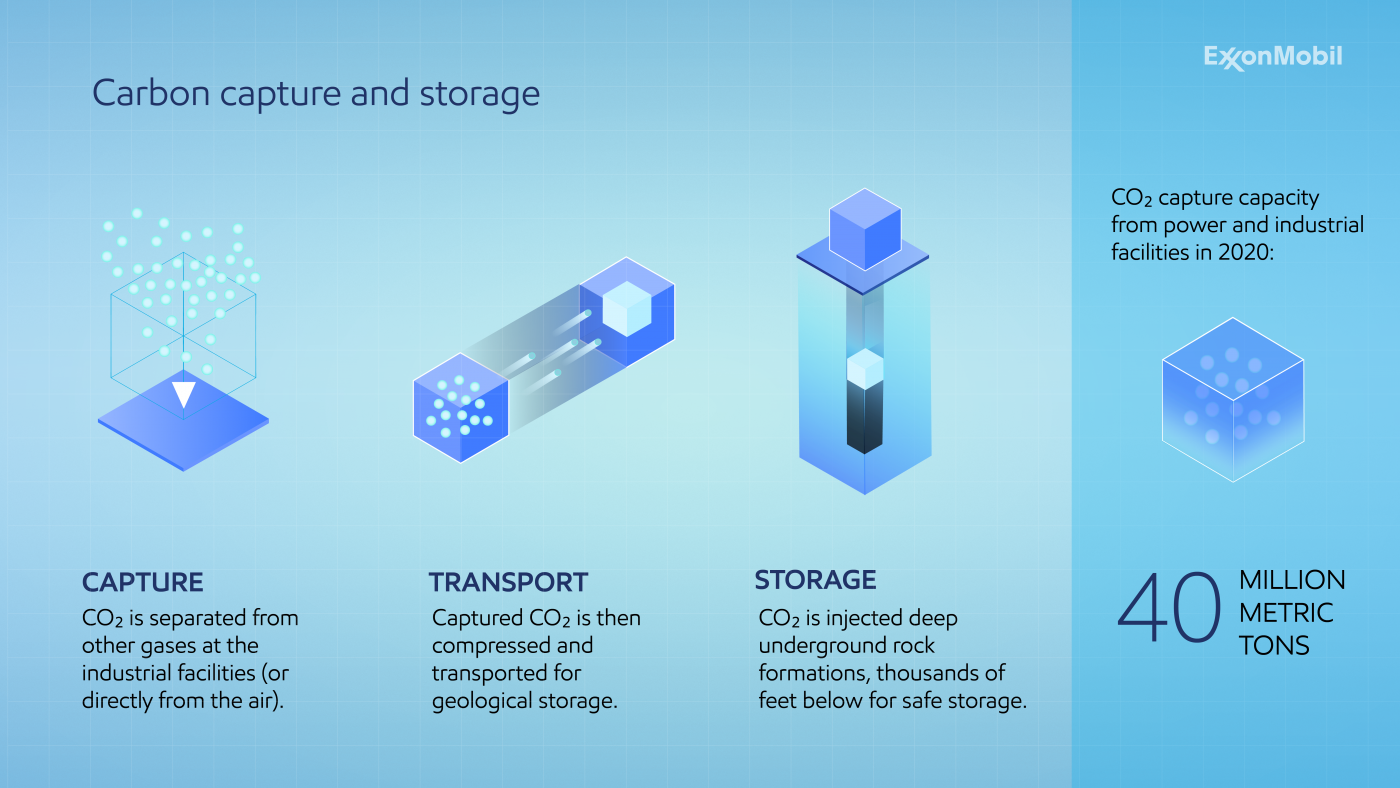

CCS could remove around 90%of CO2 emissions from industrial activity or power plants that would otherwise be released into the atmosphere, and then locks them deep underground for safe, permanent storage. This captured CO2 can also be reused for other applications that improve the quality of life.

In Asia Pacific, the number of CCS projects and studies are increasing, with ExxonMobil and its partners progressing plans in China, Singapore, Malaysia, Indonesia and Australia to capture industrial CO2 emissions from high-emitting areas and explore potential storage locations.

From transport to storage and even reusing captured CO2, we bust the myths around CCS.

How do we move captured CO2?

Once CO2 is captured, how do we get it to where it can be safely stored or utilized?

CO2 can be moved to an underground storage location or processing plant using a variety of methods, from pipelines to trucks, rail to ships. Research has shown moving CO2 is as safe as current gas transportation, and in some cases safer due to CO2’s lack of flammability.

Pipelines are the most common method of transporting CO2, with the energy industry safely doing so for decades.

Shipping CO2 is likely to be more common in Asia Pacific, with large-scale shipping similar to natural gas transportation. A single ship can move between 10,000 and 40,000 cubic metres of captured CO2.

Maritime transport can also utilize existing infrastructure and is quickly scalable.

In Europe, ships are already transporting captured CO2 from large sources to terminals for underground storage.

Can we store CO2 safely?

Decades of research and monitoring show that storing carbon dioxide underground is safe when the right locations are chosen.

A study by Carnegie Mellon University found “geologic carbon storage remains a safe option to mitigate anthropogenic climate change”.

Research by the UN’s Intergovernmental Panel on Climate Change found that CO2 stored in geological reservoirs is 99% likely to remain sequestered underground for more than 1,000 years, replicating naturally occurring processes. The IPCC added if the site is chosen correctly and managed, “the CO2 can be permanently isolated from the atmosphere.”

Alison Hortle, a senior researcher at Australia’s Commonwealth Scientific and Industrial Research Organisation (CSIRO), said safety is hardwired into choosing the right spot for CO2 storage.

“A lot of effort goes into deciding whether a site is suitable in the first place,” she said. “It takes time to understand, map and test the geology. We need to understand if it can store the CO2, then use a range of industry-standard tools to track it and predict where it will go over the long term.”

This geology often comprises thick, impermeable rock, thousands of feet underground, and well below sources of drinking water. These are often the same geological formations that kept oil and gas locked underground for thousands of years.

Over hundreds of years, this stored CO2 even begins to mineralize, and potentially become a solid material after combining with other minerals. So the longer CO2 stays underground, the safer it becomes.

ExxonMobil’s 40+ years of experience around the world has shown that CO2 stored underground in properly assessed locations, coupled with monitoring, is safe and permanent. Our constant surveillance includes both surface and deep subsurface monitoring, utilizing optical laser sensors, pressure-monitoring transponders and 4D seismicity technology.

But storage isn’t the only safe and permanent option for captured CO2.

What else can we do with captured CO2?

Not only can captured CO2 be stored safely and permanently, it can also potentially be reused to help create products necessary for modern life.

Globally, around 230 million tonnes of CO2 is used every year to produce a variety of products. The majority of this CO2, about 125 million tonnes, is used in the manufacture of fertilizers. Other applications for captured CO2 include food and beverage production, metal fabrication, fire suppression and cooling.

In Australia, ExxonMobil has found a way to both recycle CO2 emissions and help the country.

Last year, the company signed long-term supply agreements with Air Liquide and BOC to capture and reuse CO2 from the Longford Gas Conditioning Plant in Victoria. Air Liquide and BOC will build new facilities to process captured CO2 for use in water treatment and desalination, as well as in food and beverage products manufacturing, and the medical industry.

ExxonMobil Australia Chair Dylan Pugh said working closely with other industries, along with sound government policy, can help develop innovative uses for captured carbon.

“This is a great example of different industries working together to create new regional construction and manufacturing jobs, delivering improved environmental outcomes while providing a valuable product.”