Plastic packaging is critical to modern life. Many products, from medical equipment to beverages and pet food, are wrapped so that they can be moved safely and efficiently to consumers like you.

No matter what you’re buying, packaging helps protect it from outside elements and clearly show what’s inside so people know what they’re getting before they open the package.

Packaging can also extend food shelf life, helping to decrease food waste.

However, once used, packaging is often discarded, possibly ending up in landfills, incinerators or, worse, the environment. Now, advanced recycling technology from ExxonMobil, currently operational in Texas, is helping packaging manufacturers around the world play a role in a more circular economy for plastics.

Through advanced recycling, the plastic waste that ExxonMobil processes into usable raw materials is attributed to new certified-circular plastics, leveraging the mass balance free attribution approach certified by an independent third party called ISCC PLUS. Certified-circular plastics have the same quality and performance as existing products.

Customers pay a premium for certified-circular plastics, which drives demand and incentivizes more plastic waste to be collected and recycled instead of being sent to a landfill or incineration. Consumers that purchase products using certified-circular plastics also play an important role in driving this demand.

Discover how we’re working together with customers like Amcor, SEE, Scientex, Thanh Phu and UFlex to help give plastics a second life, creating a more circular economy for plastics in Asia Pacific and around the world.

Food packaging in ANZ

We’re collaborating with global packaging makers Amcor and SEE (formerly Sealed Air) to help increase plastic circularity in Australia and New Zealand (ANZ).

Amcor and SEE, both have operations around the world, make everything from food and beverage packaging, to high-tech pharmaceutical and medical packages, and even personal care product containers.

Amcor placed its first order in ANZ in April 2023 for certified-circular polymers supported by ExxonMobil’s ExxtendTM technology for advanced recycling, making Amcor the first flexible packaging maker with certified-circular plastics in the region.

Tray packaging solutions for retail available in Australia.

In July 2023, SEE announced the use of certified-circular resins from ExxonMobil in packaging trays for red meat at grocery stores in Australia, a first-of-its-kind circularity initiative in the country to widen the range of plastics that can be recycled, while ensuring the safety and quality of packaged fresh foods.

These collaborations can help address the critical challenge in driving a circular economy for food-grade plastics that have strict hygiene and performance requirements, helping to increase Australia and New Zealand’s plastic circularity and contributing to Australia’s National 2025 Packaging Targets.

More packaging in Southeast Asia that offers sustainability benefits

Southeast Asia (SEA) is also producing new packaging that helps plays a role in diverting plastic waste away from landfill or incineration.

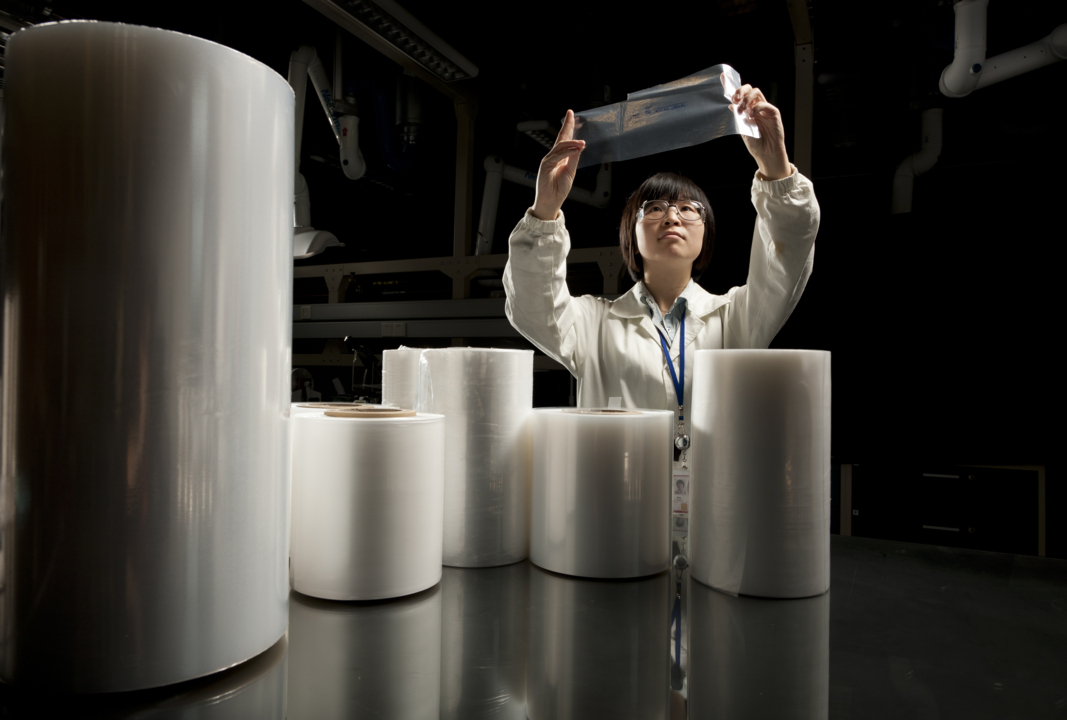

In December 2022, Scientex, a flexible plastic packaging manufacturer with headquarters in Malaysia and operations in Vietnam, the U.S. and Myanmar, started using ExxonMobil’s certified-circular plastics in its food-grade films and other flexible packaging, including for pet food.

Some examples of flexible packaging applications produced by Scientex

Thanh Phu, a global flexible packaging manufacturer headquartered in Vietnam, is also using ExxonMobil’s certified-circular plastic resins to create recyclable* mono-material flexible packaging.

Some examples of flexible packaging applications produced by Thanh Phu.

Innovation in India

India’s largest multinational flexible packaging company, UFlex, is also creating new possibilities for plastic waste in the country.

UFlex is one of the first companies in India to purchase certified-circular polymers developed by ExxonMobil, offering their customers the ability to incorporate certified-circular resins in plastic films for high-performance flexible packaging, including food-grade packaging.

The science behind plastic circularity

The key to making the above programs possible is advanced recycling.

Advanced recycling is a complement to mechanical recycling, helping to meet the growing demand for plastic circularity around the world.

Also known as chemical recycling, advanced recycling works by breaking down a wider range of hard-to-recycle plastics into raw materials that can be used to make new everyday products.

The raw materials are attributed to new certified-circular plastics, leveraging the mass balance free attribution approach certified by an independent third party called ISCC PLUS.

Customers, like the ones mentioned above, can use these virgin-quality, certified-circular plastics in existing products without requalification, and they can use them in food and medical applications with strict quality requirements.

With advanced recycling, plastic waste can also serve as an alternative to using oil and gas in the production of new products.

“Our work with packaging manufacturers like Amcor, SEE, Scientex and UFlex, will help bring the Asia Pacific region more high-performance packaging options, while diverting thousands of tons of plastic waste from landfill or incineration,” says ExxonMobil’s advanced recycling and sustainability general manager for Asia Pacific Chan Kwee Lin.

To help bring scale to advanced recycling, ExxonMobil is working in Asia Pacific to collaborate with governments, industry and technology providers to help accelerate waste collection and sorting and assess the potential for large-scale advanced recycling facilities across the region.

ExxonMobil and PETRONAS Chemicals Group Berhad have signed a memorandum of understanding (MOU) to assess large-scale advanced plastic recycling opportunities in Malaysia.

In Indonesia, ExxonMobil is exploring opportunities to secure plastic waste for processing at our advanced recycling facilities.

Our aim is to address hard to recycle plastic waste that may end up in landfill or incineration by sending the plastic instead to an advanced recycling facility. There, the plastic waste can be transformed at ExxonMobil’s facilities in Singapore, and elsewhere around the world, into raw materials used to make valuable new products we use every day.