3D printing could help industry cut energy waste, improve efficiency and reduce emissions.

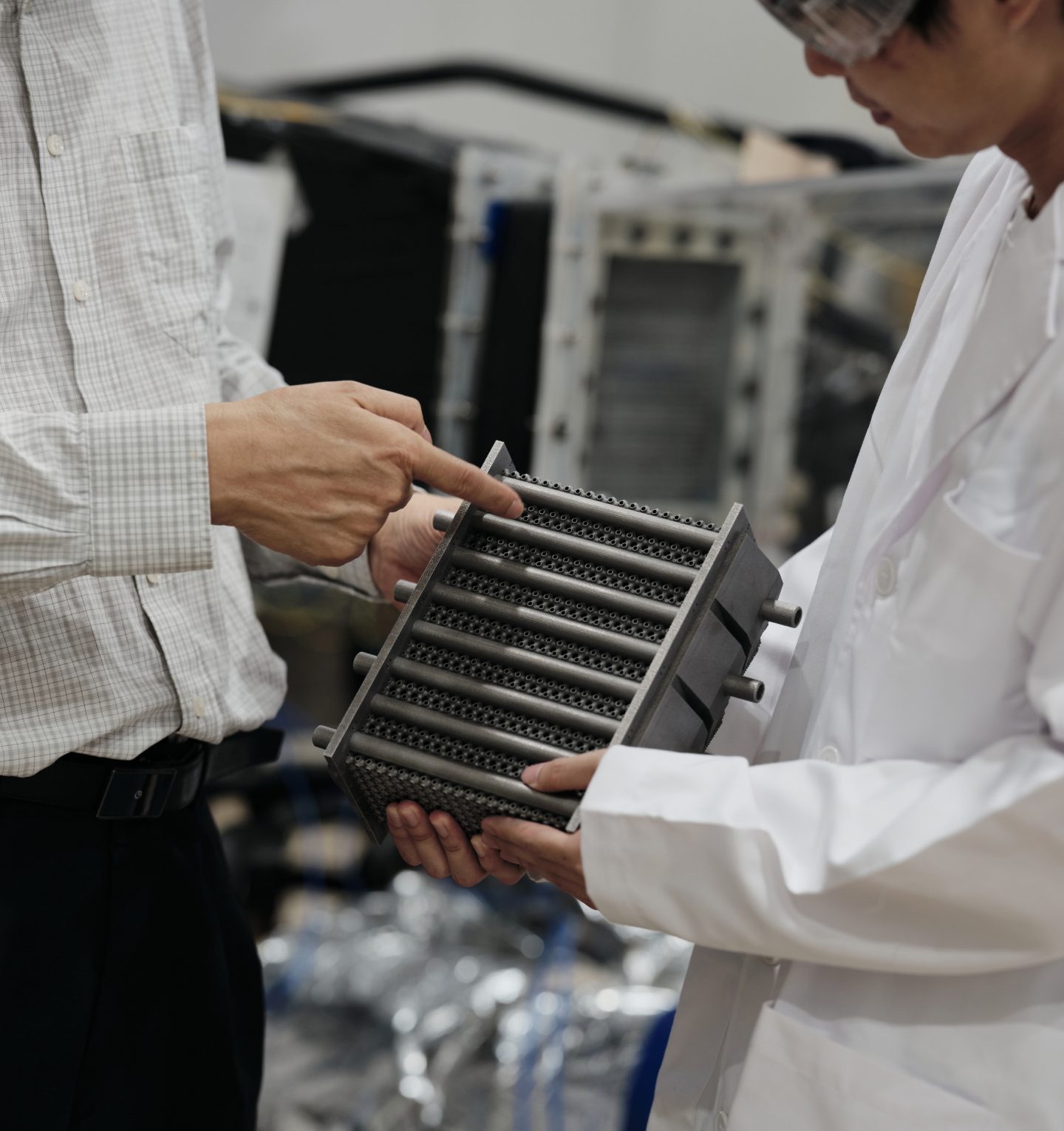

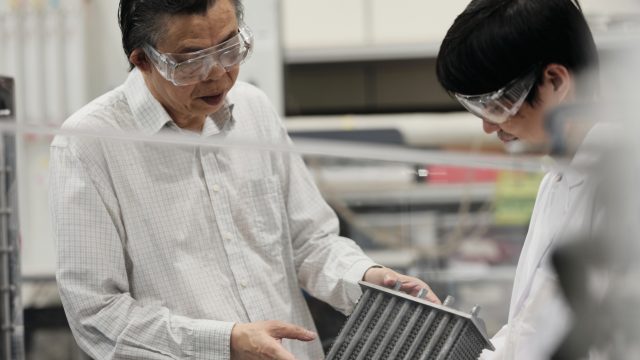

Leong Kai Choong and his team of researchers at Nanyang Technological University in Singapore are studying how metal 3D printing can be used to make highly efficient heat exchangers. These systems can then recover energy lost as so-called ‘waste heat’ and use it to power other processes.

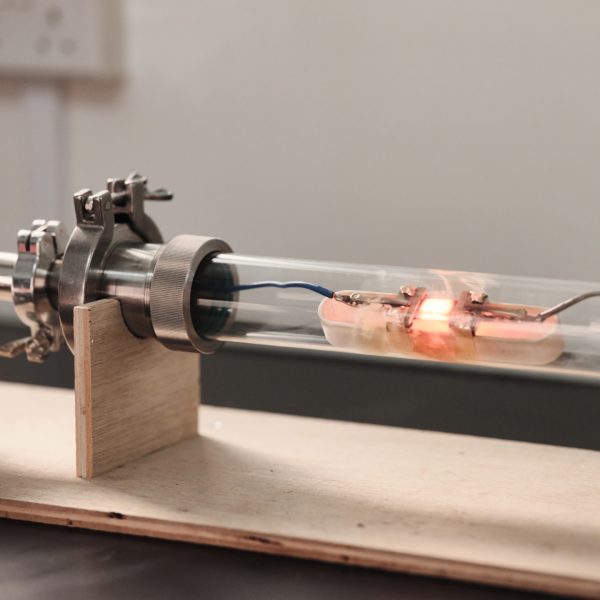

Industrial processes produce excess heat which could be lost to the environment. Heat exchangers may be used to recover this excess heat, using it to boil water to produce steam to generate additional power, or heat fluids.

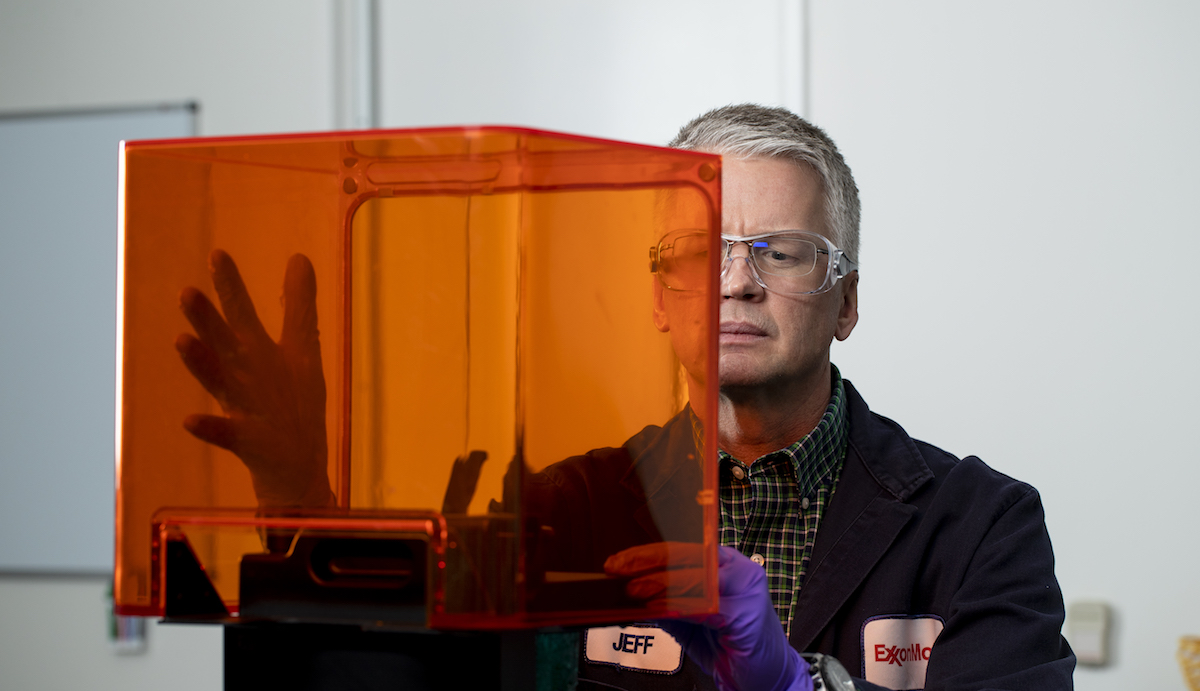

3D printing allows for more tailored and compact heat exchangers that can more effectively extract waste heat from one process and use it for another purpose. “It really boils down to more efficient heat utilization,” says Leong, who is supported in his work by ExxonMobil, the Singapore Energy Centre and the Singapore Centre for 3D Printing.

Leong adds that the reduced energy demand of the metal 3D printed heat exchangers helps cut emissions, as it means the processes can continue to work at peak capacity without requiring more energy consumption.