In the process of this growth, industrial activity is rising and the demand for energy is growing.

But the country is also facing a huge challenge: reduce its emissions intensity 45% by 2030 and reach net zero by 2070.

Industrial activity accounts for nearly a quarter of India’s emissions. While powering facilities with a lower-emission fuel like natural gas is one step towards meeting climate goals, ensuring that industrial machinery works efficiently is also essential.

Enter advanced lubricants.

When equipment runs at peak performance, it uses less energy and, therefore, produces fewer emissions.

Lubricant’s main job is to limit friction between metal parts, keeping everything moving smoothly. The more friction there is, the harder it is to keep equipment in motion, and everything can grind to a halt.

Friction also creates heat, and a high temperature within machinery is often a sign of energy inefficiency. Research shows that the right lubricant can decrease temperatures by as much as 13 °C. Overheated machinery can quickly break down, while gearboxes – which control the speed or torque of machines’ motors – can tear themselves apart and fail if underlubricated.

In addition to combating friction, lubricants offer other benefits like neutralizing acids and reducing the oxidation process, which causes machinery to deteriorate. They can also help industries save money by lowering energy costs as well as reduce maintenance costs or the need to replace equipment.

Greasing the wheels of industry

India is one of the world’s largest steel producers, and the industry is essential to the country’s economy. Making steel, however, is both energy- and emissions-intensive.

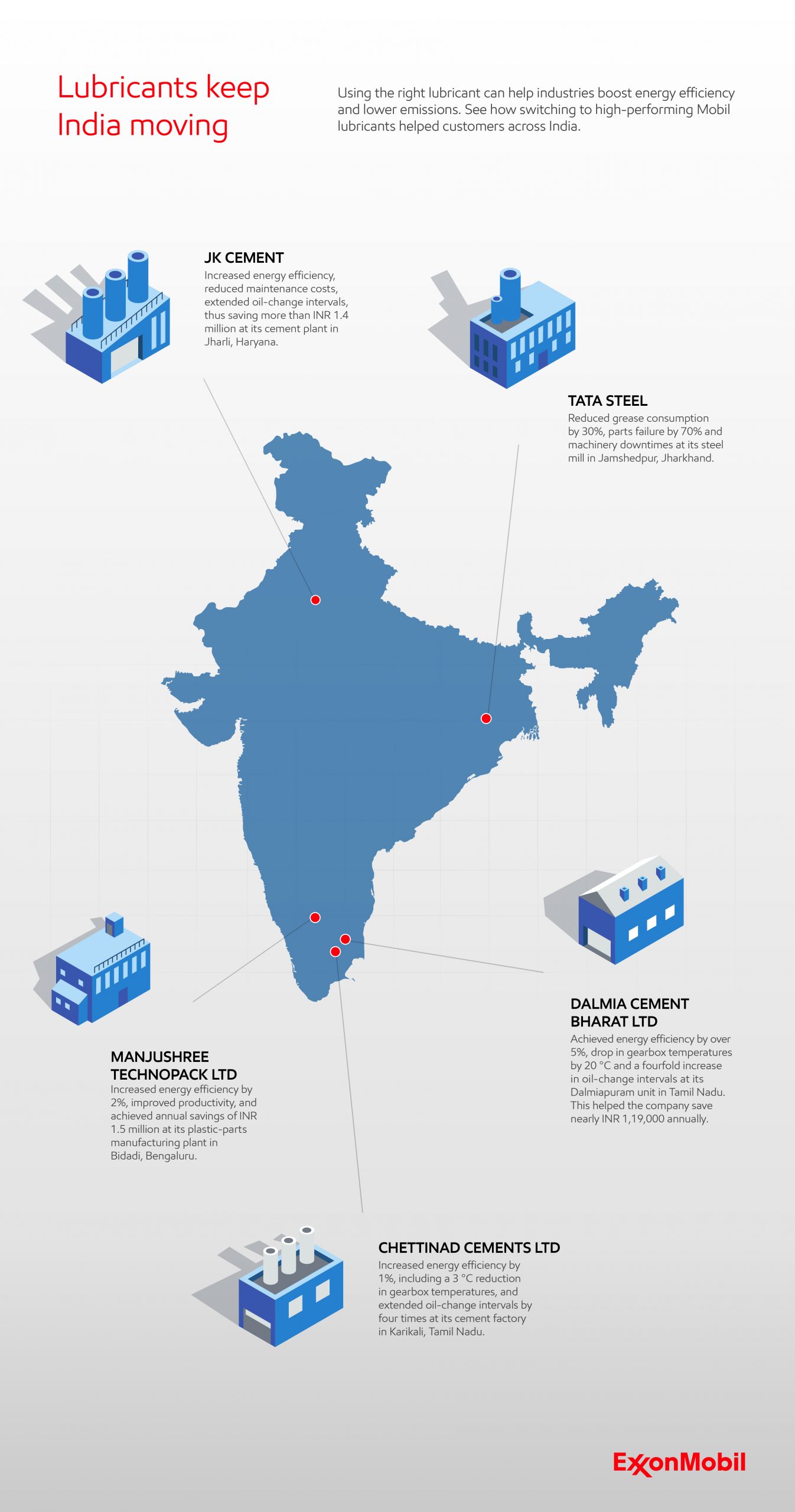

For a major manufacturer like Tata Steel, switching to Mobil lubricants at its mill helped reduce machinery failure by 70%, decreased grease consumption by a third and improved overall environmental sustainability.[2]

Keep reading to find out how ExxonMobil lubricants are helping drive energy efficiency and save customers money at other manufacturing facilities throughout India.