Today, health care workers are faced with a scarcity of protective face masks and shields, and the supply chains to produce them are taxed to their limits.

ExxonMobil staff around the world are doing what they can to help doctors and nurses breathe easier during the current COVID-19 pandemic.

In China, the company has ramped up to provide the critical polymers and elastomers needed to make protective masks, as well as the materials used in making protective medical suits, to ensure medical staff stay safe.

In Singapore, ExxonMobil plants have also worked to produce and supply materials used in the making of face masks.

In the US, ExxonMobil teams of experts in chemicals, materials science and manufacturing are offering their experience to help a collaborative effort organised by the Global Center for Medical Innovation. By quickly connecting its customers to solution providers, ExxonMobil helped create a new supply chain to respond to the medical needs in hospitals across the country.

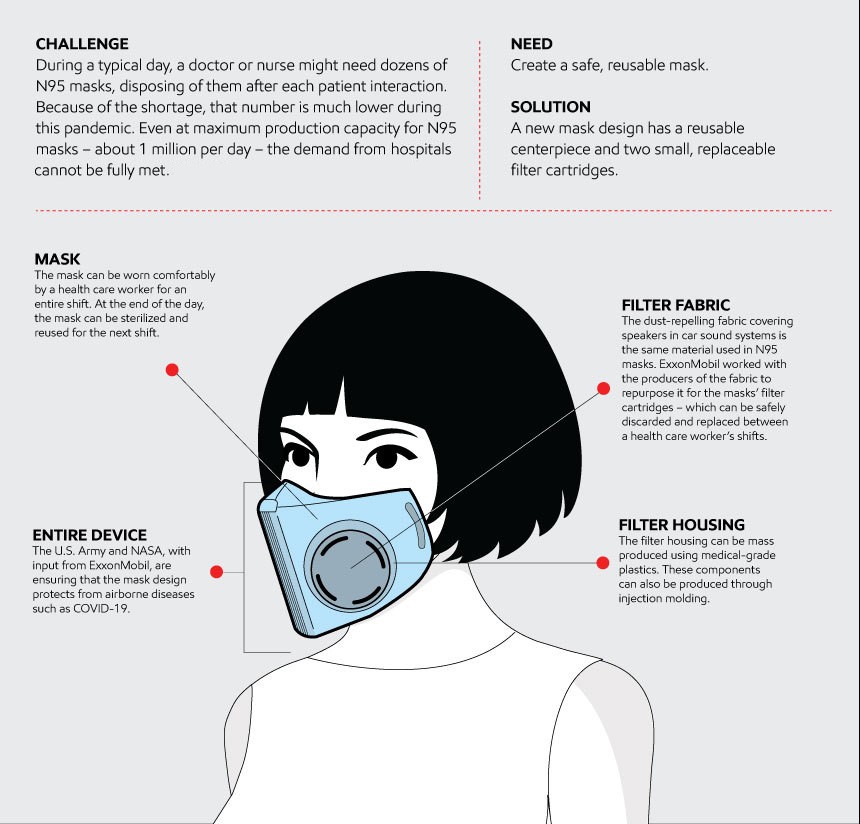

This collaboration, which represents industry, academia and government, is rethinking how protective medical equipment – specifically face shields and face masks – is made.

All this happened in just a matter of days. So far, 50,000 face shields have been produced, and production facilities are ramping up to manufacture upwards of 170,000 per hour. The collaboration has also produced models for a new, reusable face mask design that will address the shortage of crucial N95 protective masks.

Here’s a look at that newly designed medical face mask and what makes it an essential tool in fighting the spread of the coronavirus.